Products & Services

Your experts in Industrial Ammunition Disposal Technologies

Basic Engineering

The Basic engineering can be defined by customer specific regulatory rules. Typically, it contains

all things necessary to get the regulatory approval for the site:

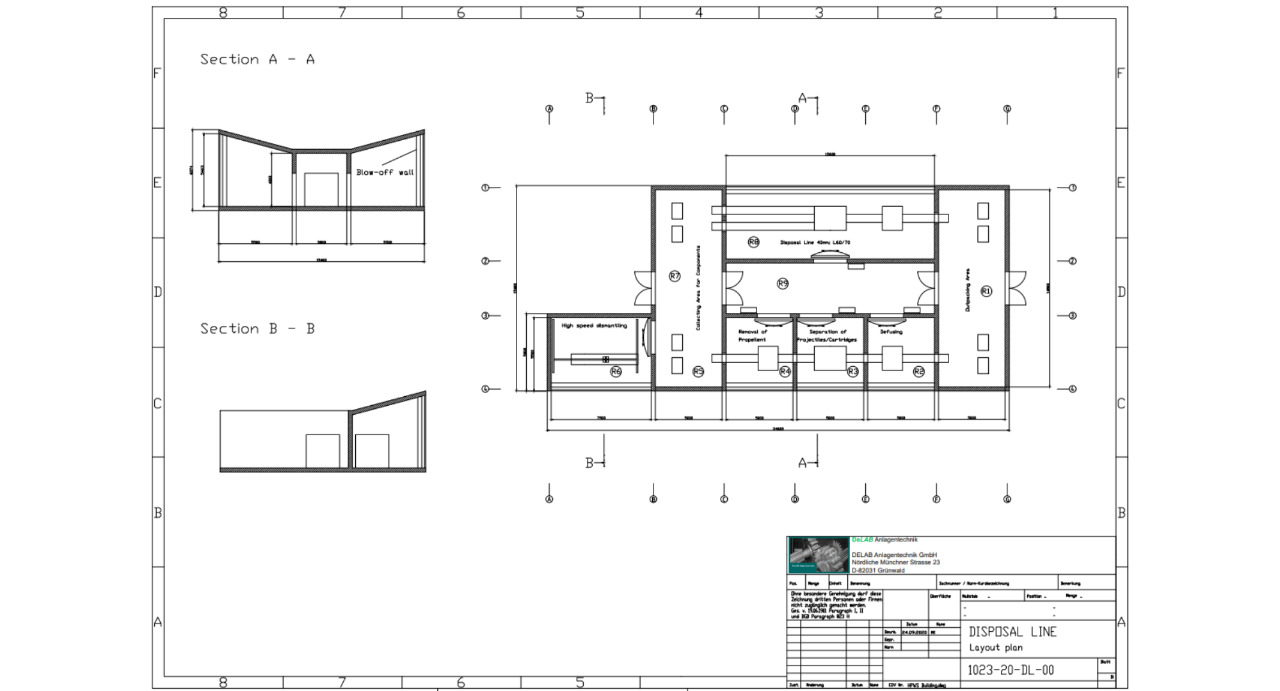

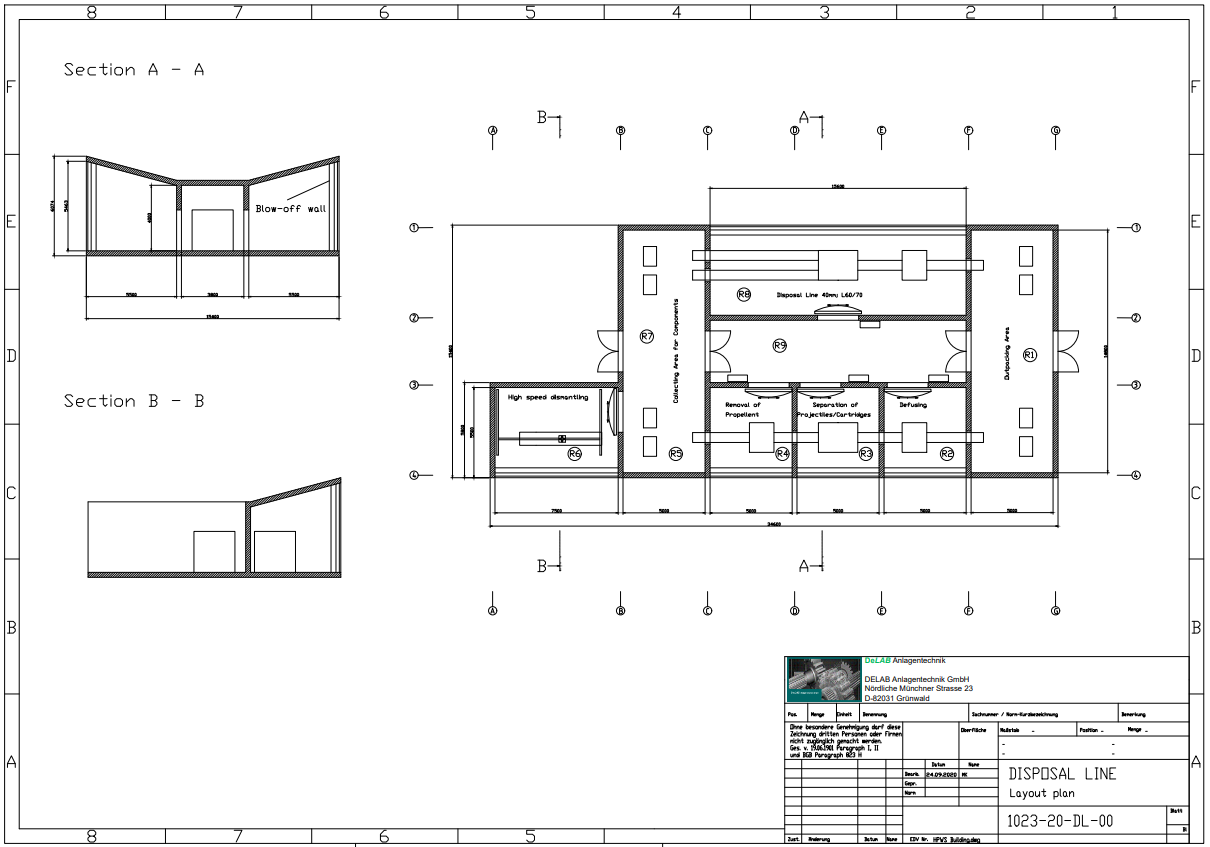

- Flow charts

- P&I Diagrams

- Drawings

- Static calculation / Room data sheets for building(s)

- Material balance (quality and quantity of necessary media supply)

- Description of all provided machinery

- Time schedules

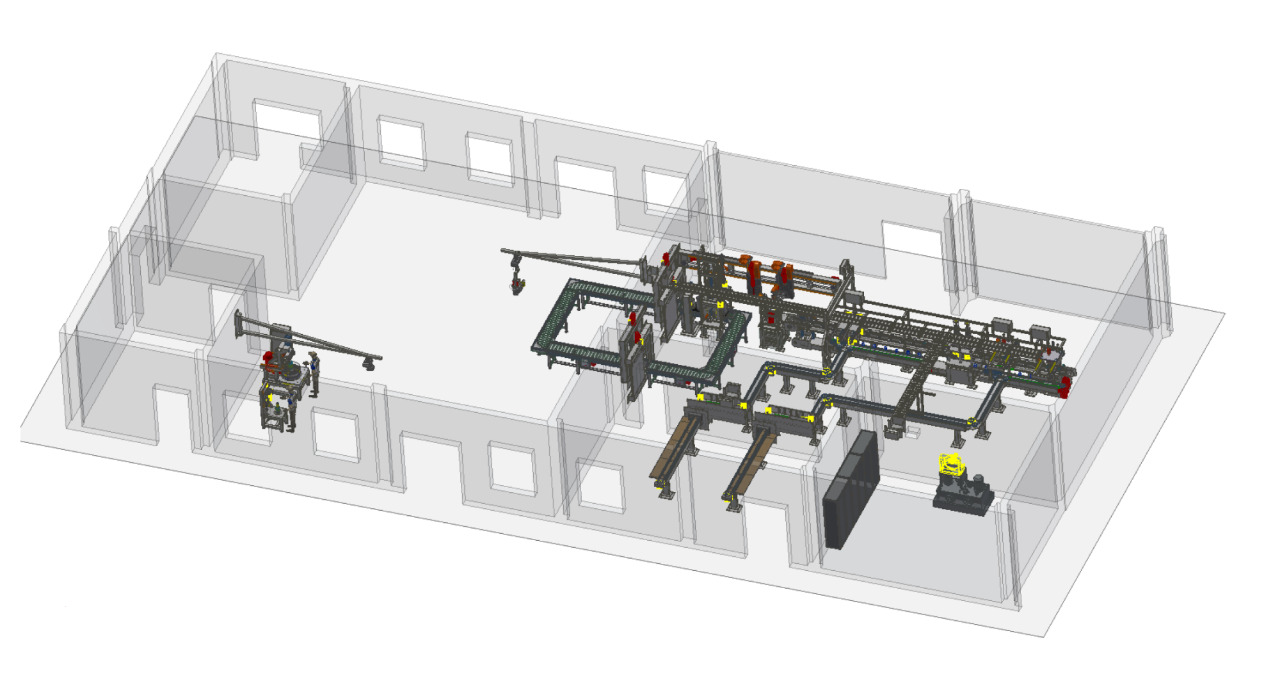

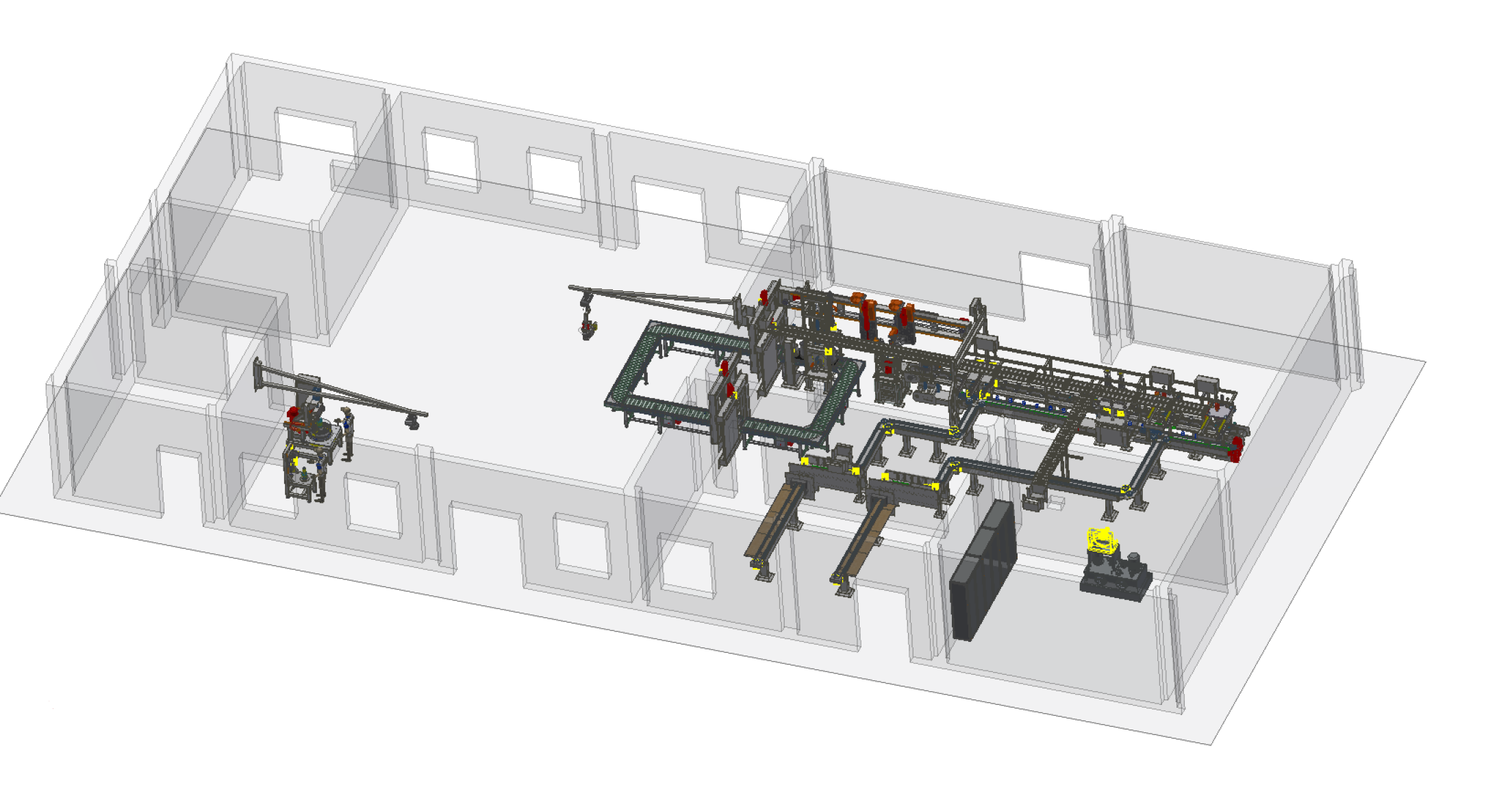

Detail Engineering

The Detail engineering provides the customer with everything necessary to prepare

the site for installation. Typically, it contains:

- Refined P&I Diagrams

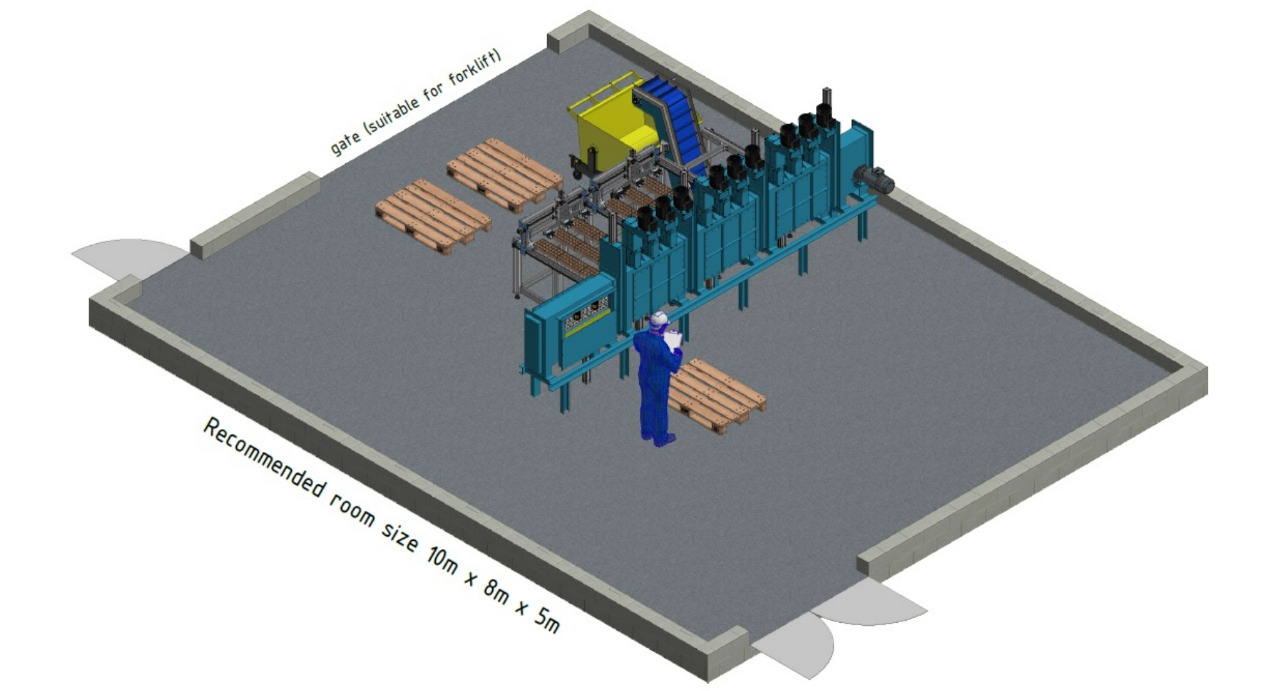

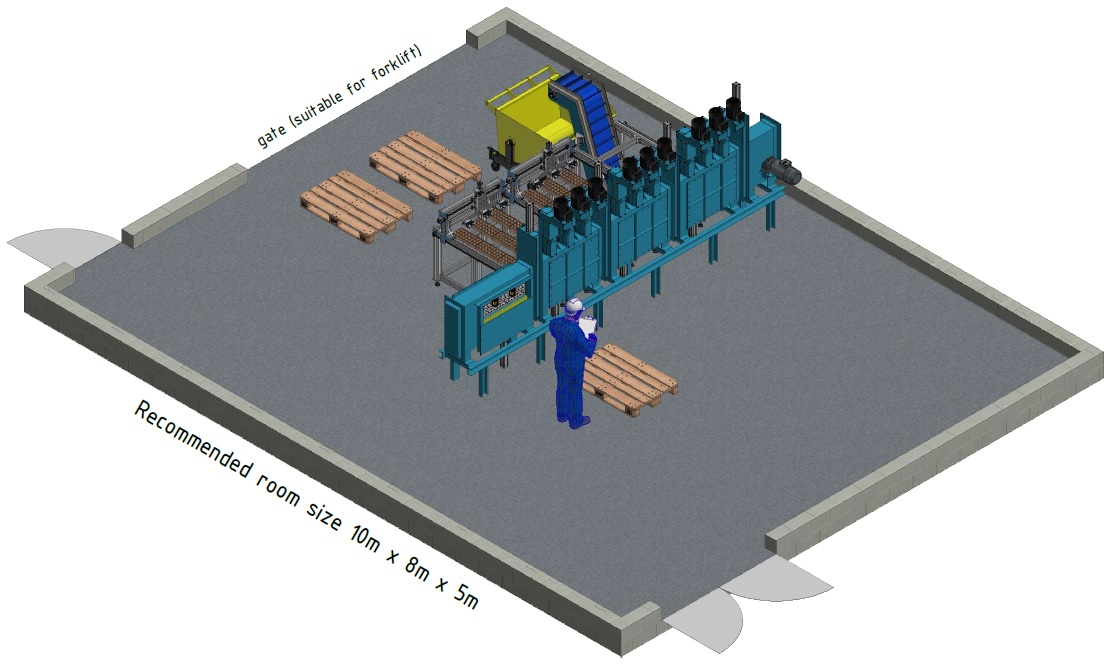

- Drawings and 3D CAD models

- Environmental impact

- SCADA system integration, E-Plan

- Preliminary operating manual

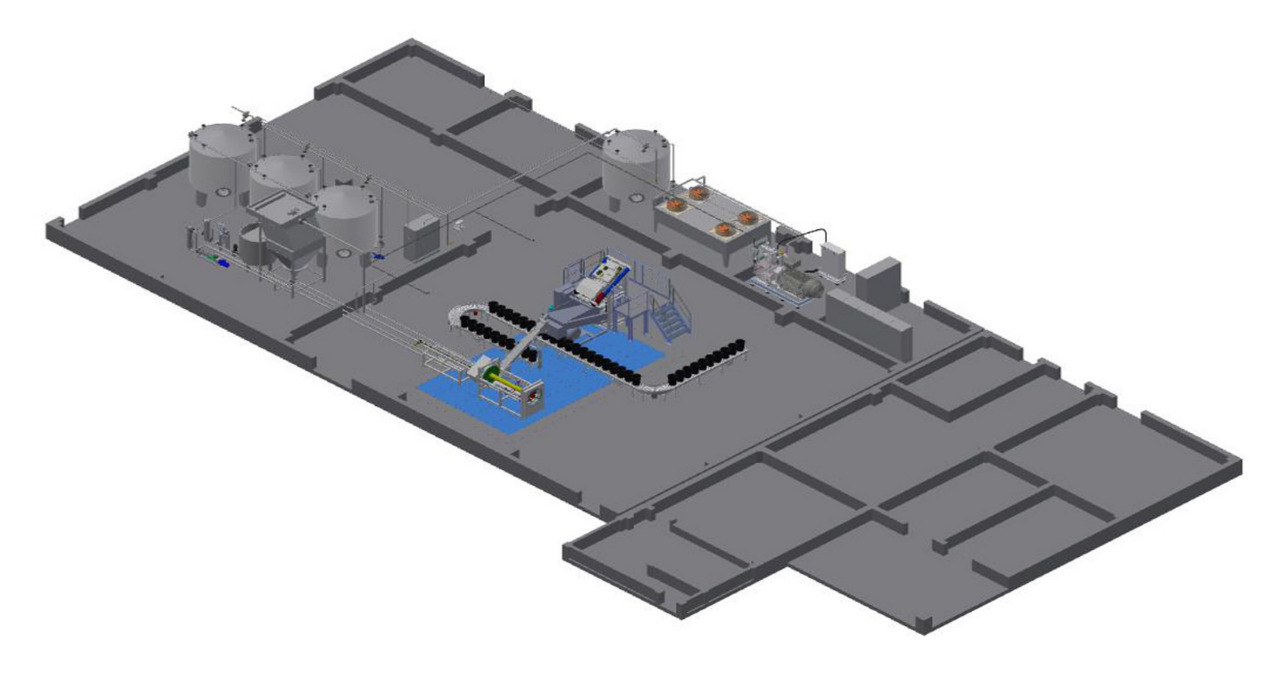

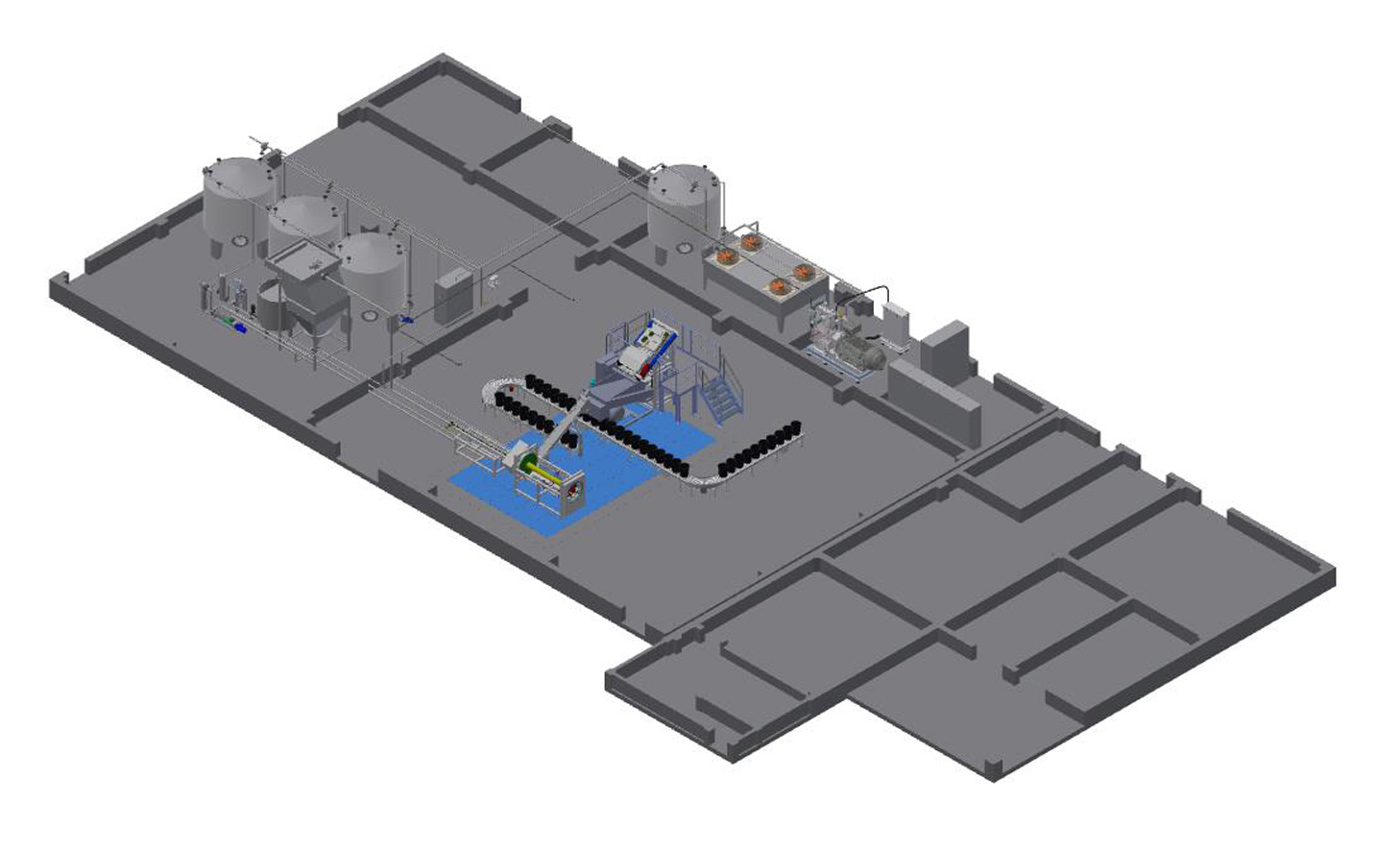

Custom made Equipment

As per customers request; for example the thermal treatment plant (TTP) incorporates several different demil machines in such a way, that the entire treatment chain can be applied to the customers ammunition, while optimizing throughput, staffing, automation and media consumption while fully observing environmental protection requirements.

Fuze Disassembly Machine FDM

Fully automatic disassembly of fuzes into metal scrap and explosives

Flashing Furnace FF

Flashing of empty ammunition pieces; completely removes residual explosives, paint markings etc. from ammunition scrap and leaves only fully inert metal scrap.

High Pressure Water System HPWS

Washing out of explosives from ammunition such as rocket motors; this non-destructive method leaves the metal parts of the ammunition intact while only removing the explosives/propellants.

Improved Conventional Ammunition Machine ICM

Destruction of clusterbombs / bomblets.

Plasma Furnace PF

Destruction of armor piercing bomblets and cluster ammunition.

Rotary Tube Furnace RTF

Large throughput destructive treatment of loose explosives, propellants and other burnable material.

Static Detonation Kiln SDK

Destruction of small calibre ammunition without disassembly. Can handle a variety of non-armour piercing ammunition and explosive devices: Hand grenades, Anti-personnel mines, Pyrotechnical devices, Car-airbags, etc.

Static Burn Out Kiln SBO

Fully automated burn out of untamped explosives, such as propellants, NC double base or single base, powder-like explosives, etc.

Underwater Sawing System UWS

Remotely operated sawing system, for cutting large and medium calibre ammunition as preparation for further treatment steps (i.e. melt out processes).

In order to extend the life cycle of your equipment, we support you with services such as regular maintenance including procurement, delivery and installation of spare and wearing parts and if necessary, troubleshooting procedures on your system. In this way you keep your plant running and always state-of-the-art.

Customer specific waste treatment solutions

We can offer several waste treatment options for a full end-to-end disposal process. Our experience with ammunition allows us, to offer solutions for difficult waste treatment problems in other industries too.

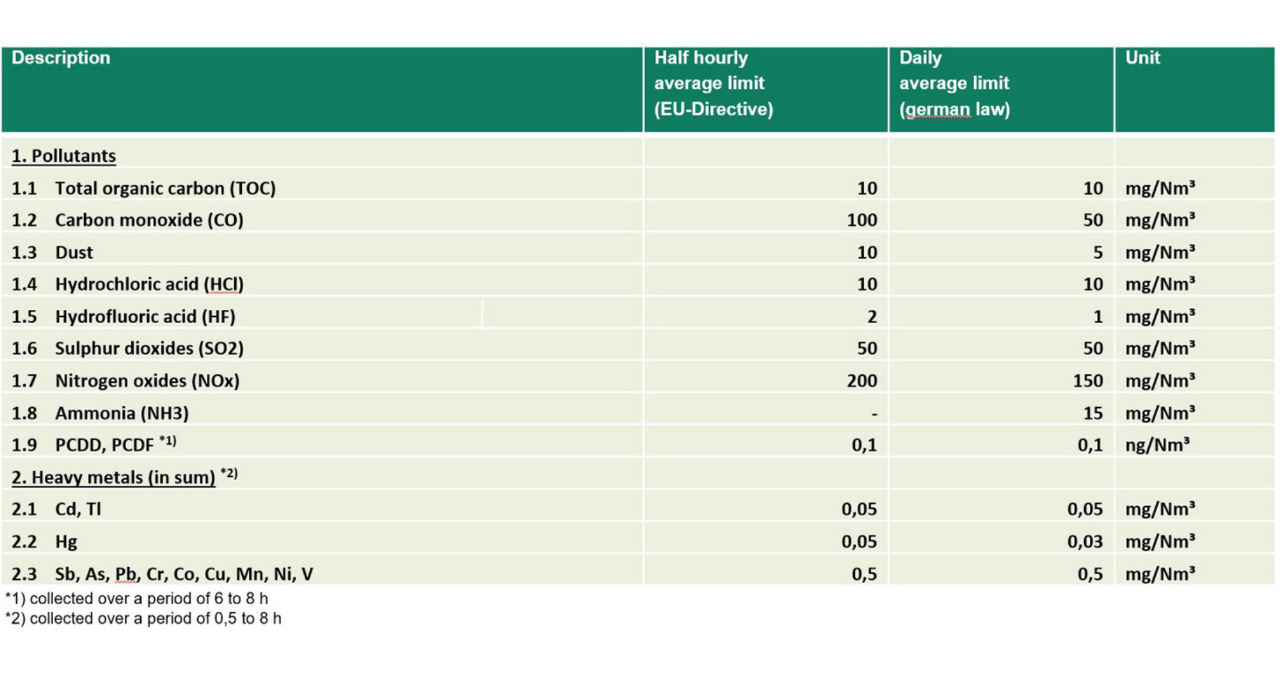

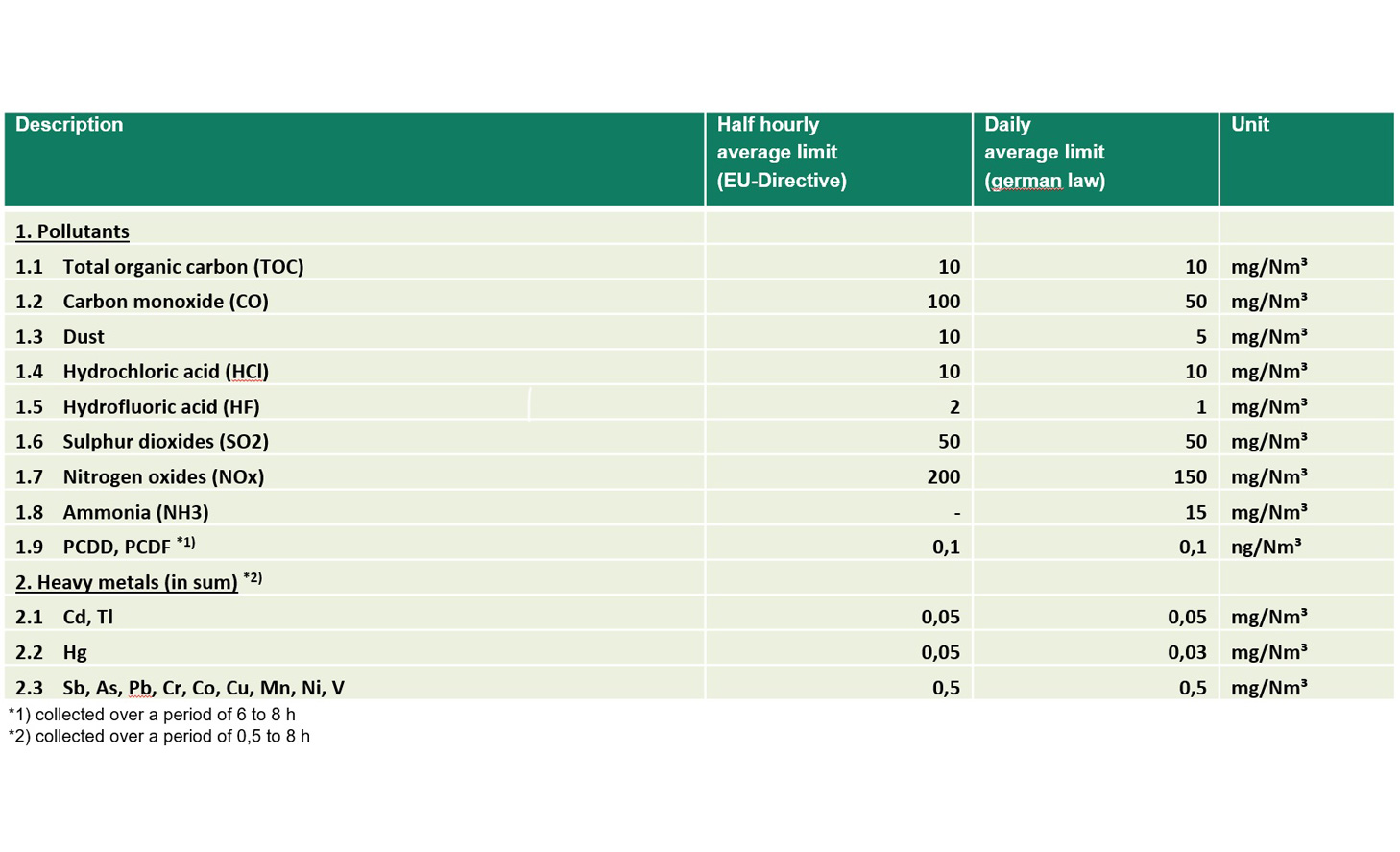

Off Gas Treatment System OGS

Fully automatic system for the treatment of waste gases from our other applications. This system is always tailored to the specific customer application, observing local laws as well as the european emission directives (i.e. 2010/75/EU).

Water Purification System WPS

Optional recycling of waste water in the case of wet demil applications. Greatly reduces the fresh water consumption of the plant.